After soaking, washing, and the removal of the flesh, wool/hair, followed by a chemical treatment, we get a semi-product called Pickl.

We get that semi-product by acidifying hides with a sulfuric or formic acid with the addition of neutral salt. As it is, Pickl is used in further production as raw material for making Wet Blue or It is stored and sold to our customers.

We offer lamb, sheep, and goat Pickl. Pickl, just like Wet Blue, is sold in many categories whose ratio depends on agreement with our customers.

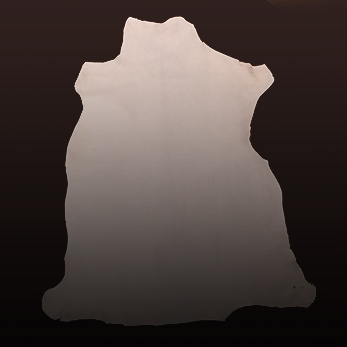

Lamp Pickl

Daily capacity: 2000pc

Assortment: 30%, 30%, 30%, 10%

Packaging: 500pcs/pallet

Preservation method: Semi-preserve

Size: 0,45 - 0,60m2

Sheep Pickl

Daily capacity: 2000pcs

Assortment: 30%, 30%, 30%, 10%

Packaging: 500pcs/pallet

Preservation method: Semi-preserved

Size: 0,45 - 0,60m2

Goat Pickl

Daily capacity: 2000pcs

Assortment: 70%, 20%, 10%

Packaging: 500pcs/pallet

Preservation method: Semi-preserved

Size: 0,45 - 0,60m2

Through the process of tanning raw hides, which starts mechanically and then continues with chemicals, we get a semi-finished product known as Wet Blue.

For the process of producing Wet Blue, raw material is chosen from within our stock that satisfies all the requirements of our customers.

Wet Blue produced in our tanning department is of excellent quality, with full substance and is well-tanned without traces of wool and hair.

In our tanning department, we produce lamb, sheep, goat, calf and, beef Wet Blue.

All produced Wet Blue is classified into four categories: I (1st), II (2nd), III (3rd), IV (4th), and we sell it like that.

The ratio of categories when selling depends on a mutual agreement with our customers. Currently, our daily capacity of lamb/sheep Wet Blue is cca. 1500/2000 pieces. All Wet Blue is exported to our customers in Italy, Spain, and Poland.

Lamb Wet Blue

Daily capacity: 2000pcs

Assortment: 30%, 30%, 30%, 10%

Size: 0,45 - 0,60m2

Packaging: 500pcs/pallet

Tanning*: Fully tanned

Split: No

*can be tanned using Wet White

Sheep Wet Blue

Daily capacity: 2000pcs

Assortment: 30%, 30%, 30%, 10%

Size: 0,45 - 0,60m2

Packaging: 500pcs/pallet

Tanning*: Fully tanned

Split: No

*can be tanned using Wet White

Goat Wet Blue

Daily capacity: 2000pcs

Assortment: 70%, 20%, 10%

Size: 0,45 - 0,60m2

Packaging: 500pcs/pallet

Tanning*: Fully tanned

Split: No

*can be tanned using Wet White

Calfskin Wet Blue

Daily capacity: 300pcs

Categories: 8/13, 13/19

Split: No

Packaging: 100 – 150pcs/pallet

Tanning method: Full Wet Blue

Further in the process, by tanning the Wet Blue, we get a semi-finished product called Crust.

Hides in the Crust phase get their properties like basic color, softness, and, if needed, hydrophobicity.

In this phase, we prepare the hides depending on what purpose it is going to be used for; that is, will it be used for the cobbler program or clothing program.

The semi-finished product Crust can be stored like it is and sold like that, or it can go through further processing.

This further process is where Crust gets its different colors and varnishes. This way we get final products that will be used for clothing and cobblering.

Currently, we offer lamb/sheep, goat, and veal Crust. Just like with Wet Blue, we offer Crust in four categories, depending on the agreement with our customer.

Lamb Crust

Daily capacity: 1000pcs

Size: 0,45 – 0,60m2

All colors: YES

Anilin colouration: YES

Colouration: 100%

Ironed

Softened

Sheep Crust

Daily capacity: 1000pcs

Size: 0,55 – 0,90m2

All colors: YES

Anilin colouration: YES

Colouration: 100%

Ironed

Softened

Goat Crust

Daily capacity: 1000pcs

Size: 0,45 – 0,60m2

All colors: YES

Anilin colouration: YES

Colouration: 100%

Ironed

Softened

Calfskin Crust

Natur

Daily capacity: 500pcs

All colors: YES

Ironed

Softened